Dissertation

Silk Jacquard Fabric

Silk thread is an extremely fine animal fiber. Where one strand of hair is 50 to 60 denier (a unit of thread thickness), in comparison silk is the thinnest of threads at 2 to 3 denier and when you twist numerous strands together you finally get a thickness that is over 10 denier. When you take this thin thread and create fabrics that are densely woven, it can create beautiful patterns and textures, however on the other hand it is true that it can be very difficult to handle.

| Category: | Material |

|---|

| Date: | 2023.08.01 |

|---|

| Tags: | #fw23 #silk #silkjacquardfabric #visvim |

|---|

Silk thread that comes from the cocoons of silkworms are single stranded threads made of a protein secreted by silkworms that can reach lengths of up to 1,500 meters. Fabrics that are made with silk thread have a tautness to them and are also very durable, they possess excellent water absorbency and moisture permeating properties as well, all while maintaining a beauty and suppleness. They have long attracted the attention of people as a luxury item with an elegant luster and soft hand feel.

Yonezawa in Yamagata Prefecture is known as a production area of silk fabrics that ranks alongside other well-known areas like the Nishijin district in Kyoto and the Kiryu area of Gunma, of which its roots go back to the Edo period. Harunori Uesugi the 9th feudal lord of Yonezawa Domain enacted a policy of economic reform for his clan when he allowed the women and girls of the samurai class to learn how to weave. Their work was eventually exported to Kyoto and the surrounding areas and became known as "Yonezawa Ori"(Yonezawa textile).

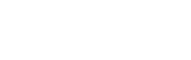

When the country opened its borders during the Meiji period they began exporting their fabrics overseas and fully developed into an area known for its textile production. Even now Yonezawa is home to many companies and workshops that deal with textiles, and among them Namikata Kogyo Inc. was founded in the year Meiji 28 (1895) and they produce fabric for clothing while specializing in silk. Inside this workshop, warping is conducted in the old-fashioned way, adjusting the length and number of warp threads when setting the silk threads on the loom.

Silk thread is an extremely fine animal fiber. Where one strand of hair is 50 to 60 denier (a unit of thread thickness), in comparison silk is the thinnest of threads at 2 to 3 denier and when you twist numerous strands together you finally get a thickness that is over 10 denier. When you take this thin thread and create fabrics that are densely woven, it can create beautiful patterns and textures, however on the other hand it is true that it can be very difficult to handle.

To create fabrics made from silk, it requires a lengthy process of preparing the threads before placing them on a loom because of the natural characteristics found in silk thread. Prior to warping, silk threads that have been dyed and gathered in skein form are separated into smaller batches on a spool and rolled up in a preparatory step of the process known as "ito-wari" or thread division. Once all the threads have been separated, approximately 200 hexagonal spools (the number will vary depending on the width of the fabric) are arranged on an enclosure on the floor that is about 10 square meters and has a thin layer of sand laid out. Single strands of warp thread are then pulled from each spool and collected together before passing through the eyes of a closed off comb like apparatus known as an "Ara-osa" that winds up all the thread on the other end after it passes through. Most of the processes and techniques described have been used and remain unchanged for over 100 years. In modern times it has become more common to see warping machines that utilize bobbins to wind large amounts of warp threads around a drum at high speeds, but if the required production volumes are less these old methods can still be used to produce fabrics today. The reason for laying sand under the wooden frame is to prevent the threads from breaking when the warping process stops and causes the tension of the thread to loosen where they fall, hang down, and get entangled which can lead to breakage. The shape and size of the wooden frames were also derived from the years of experience our predecessors had working with silk.

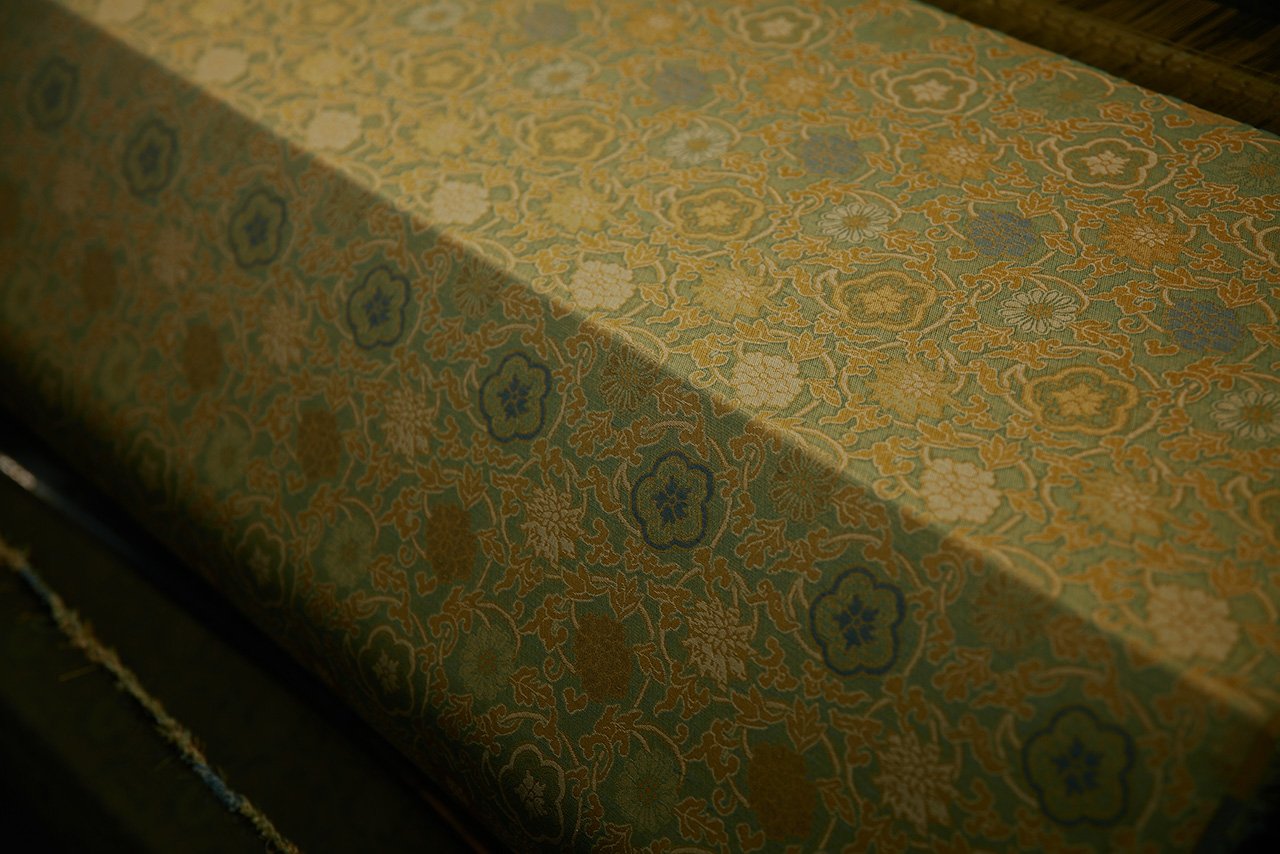

Once all the preparation is complete, the warp and weft threads undergo the warping step and are then placed onto the loom before being woven up. At the weaving facility of "Abekichi Co., Ltd." established in Meiji 43 (1910), the craftsmen operate a jacquard loom that is able to express complex patterns. They also take great precautions and demonstrate their expertise to avoid damaging or breaking the delicate silk threads.

"Initially I didn't pay as much attention as many of these fabrics gave off a strong impression of decorative women's garments," said Hiroki Nakamura, Creative Director of visvim when asked about these specific sorts of silk jacquard weavings. "However, as I searched through old archives, I learned that silk fabrics were used for details such as the lining of samurai armor and the scabbards of katana swords and I became much more intrigued. I am drawn to the excellent functions of silk as a natural material, as well as the weaving techniques that were cultivated to align with the native characteristics of silk."

Text: Kosuke Ide

Photo, Movie: Keisuke Fukamizu

Movie edit: cubism