Dissertation

Horween Leather

For the past 100 years, on the outskirts of downtown Chicago in the mid-western United States, a long-established leather tannery has been in operation. My first visit to this tannery was a few years ago. While there, the fourth generation owner, a passionate individual named Skip, explained the traditional process of manufacturing Cordovan that his family has closely maintained over the last century.

"In the past, horses were a common form of transportation in America, so it was much easier to source horsehide and their shells, Cordovan's raw-material."

| Category: | Material |

|---|

| Date: | 2009.08.01 |

|---|

| Tags: | #chicago #cordovan #horweenleather #visvim |

|---|

Chicago's Fifth Generation Craftsman

For the past 100 years, on the outskirts of downtown Chicago in the mid-western United States, a long-established leather tannery has been in operation. My first visit to this tannery was a few years ago. While there, the fourth generation owner, a passionate individual named Skip, explained the traditional process of manufacturing Cordovan that his family has closely maintained over the last century.

"In the past, horses were a common form of transportation in America, so it was much easier to source horsehide and their shells, Cordovan's raw-material."

He continued his thorough explanation as he showed me each Cordovan shell one by one, which is characteristically supple by nature with a fine texture and distinctly glossy sheen.

"The fibers in Cordovan are so remarkably tight that initially they made strops with them, a leather strap used to sharpen straight-razors. Then you started seeing this distinct glossy texture in horseback riding boots, as well as shoes for military officers. Gradually this prized Cordovan, which is extremely durable, became better known for its use in men's footwear and earned a reputation as being a unique and preciously valued leather."

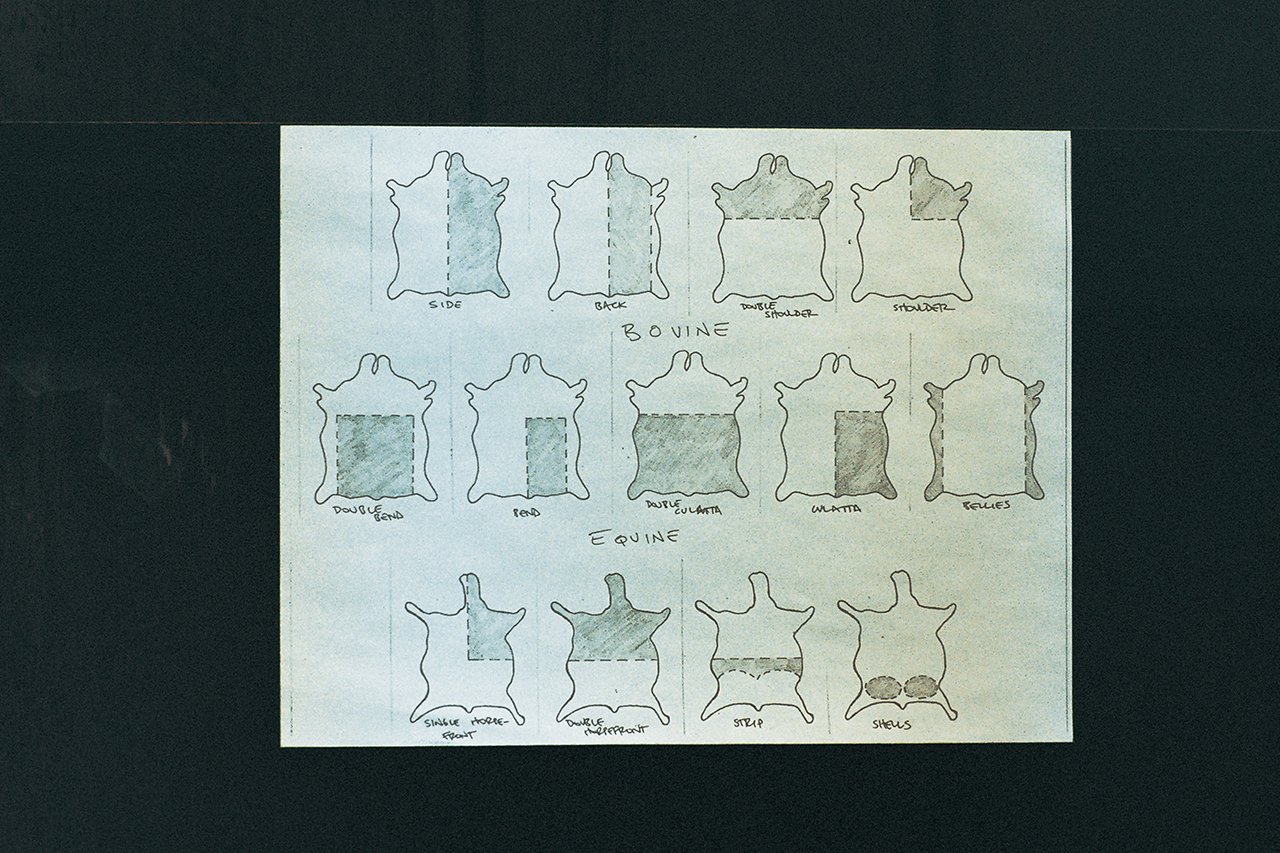

Cordovan is not like leathers that come from hides; rather, it is a fibrous membrane found between the hide and muscle on the posterior of a horse.

"Our Cordovan is tanned in pits using vegetable tannin for no less than 6 months. As far as I know there are only two companies in the world, including ours, that produce cordovan. We take our time to slowly tan the shells in pits because we believe this method allows us to make the best cordovan."

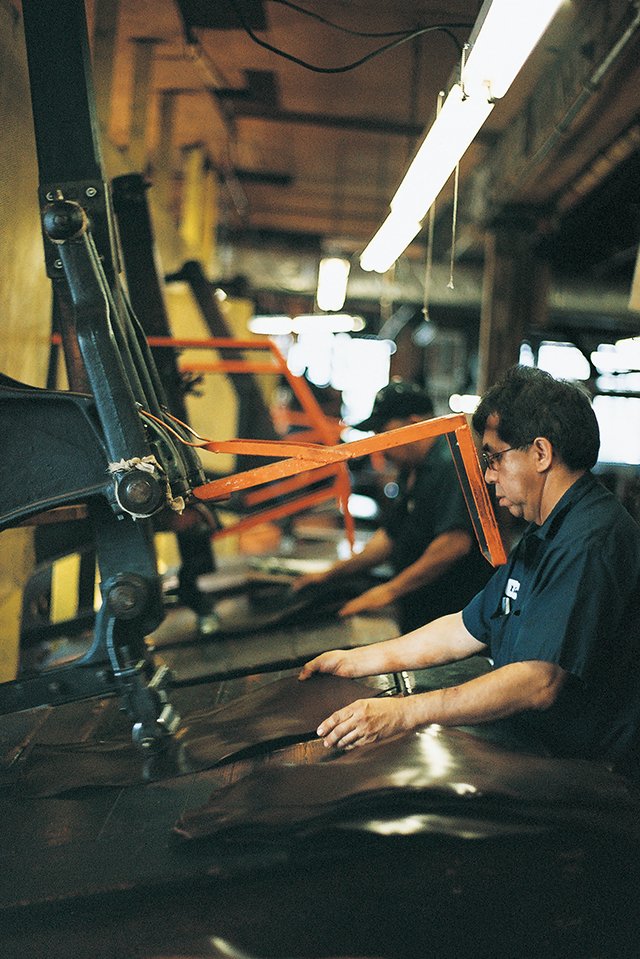

The downtown factory is a redbrick edifice that has likely changed very little since it was first constructed, as one is able to sense the history. The tanning process begins at ground level, where horsehides are trimmed in preparation for pit tanning. As you move through the second and third floors, hides are dried, polished, and the sections of the Cordovan shells are meticulously cut out by hand. The process required to make this incredible material is definitely not easy. Inside the factory, seasoned artisans work with smiles on their faces. Their passion and pride, things obviously inherited, create Cordovan of unparalleled quality.

Skip's executive office shows signs of a family-owned business; the room is adorned with pictures of relatives, past presidents, and of course the founder. Skip jokes around and laughs while telling us, "This is my daughter. She rides horses; horses have always taken care of our family. My son is a chef in New York right now, and he actually seems to be pretty familiar with you and with Visvim."

"Well, I'm honored."

"This vintage motor boat here is my hobby and I always look forward to the weekend when I take it out on Lake Michigan," continues Skip, as the warm, friendly conversation goes on.

There are not many tanneries left in America, most have relocated overseas or closed down their businesses. It must be difficult upholding a high level of quality while adhering to the traditional methods of leather-tanning. There doesn't seem to be many family businesses that continue making a good product with the integrity and enthusiasm of Skip's.

This year I returned again to their factory in Chicago. Skip was there to pick me up when I arrived at O'Hare airport. As I got into his car, he announced with an enormous smile, "Hiroki, my son Nick will be working with me now."

"Really? This means the lineage will continue!"

It is difficult to explain, but at that moment, Skip's joy felt as if it were my very own. I'm very much looking forward to working with the fifth generation.

Dissertation on The Authenticity of Utility / Published by cubism inc. 2009