Dissertation

Pile Fabrics

What word would best help people to visualize pile fabrics? Fleece, perhaps? However, as fleece is defined as a "Fabric with a napped surface that is made by circular knitting polyester or another material", it becomes evident that pile fabrics are something completely different.

| Category: | Material |

|---|

| Date: | 2022.09.27 |

|---|

| Tags: | #fw22 #kouyaguchi #pilefabrics #visvim |

|---|

Pile Fabrics and Fleece

What word would best help people to visualize pile fabrics? Fleece, perhaps? However, as fleece is defined as a "Fabric with a napped surface that is made by circular knitting polyester or another material", it becomes evident that pile fabrics are something completely different.

Fleece as we know it today was created by Yvon Chouinard of Patagonia, and Malden Mills. As the well-known story goes, during the '70s, Chouinard had been dissatisfied with how uncomfortable wool sweaters were when they became wet due to sweat or rain and from a wish to create his own polyester pile jacket as an alternative to this, he drew inspiration from the polyester pile sweaters he had seen fisherman wearing. After the initial development of his fleece, adjustments were made over the coming years, and finally in the '80s, the Synchilla Fleece was introduced as an affordable fabric that protected against the cold. It was quickly adopted by various fast fashion brands, making it a worldwide sensation. The word fleece has since become synonymous with the material that they had developed.

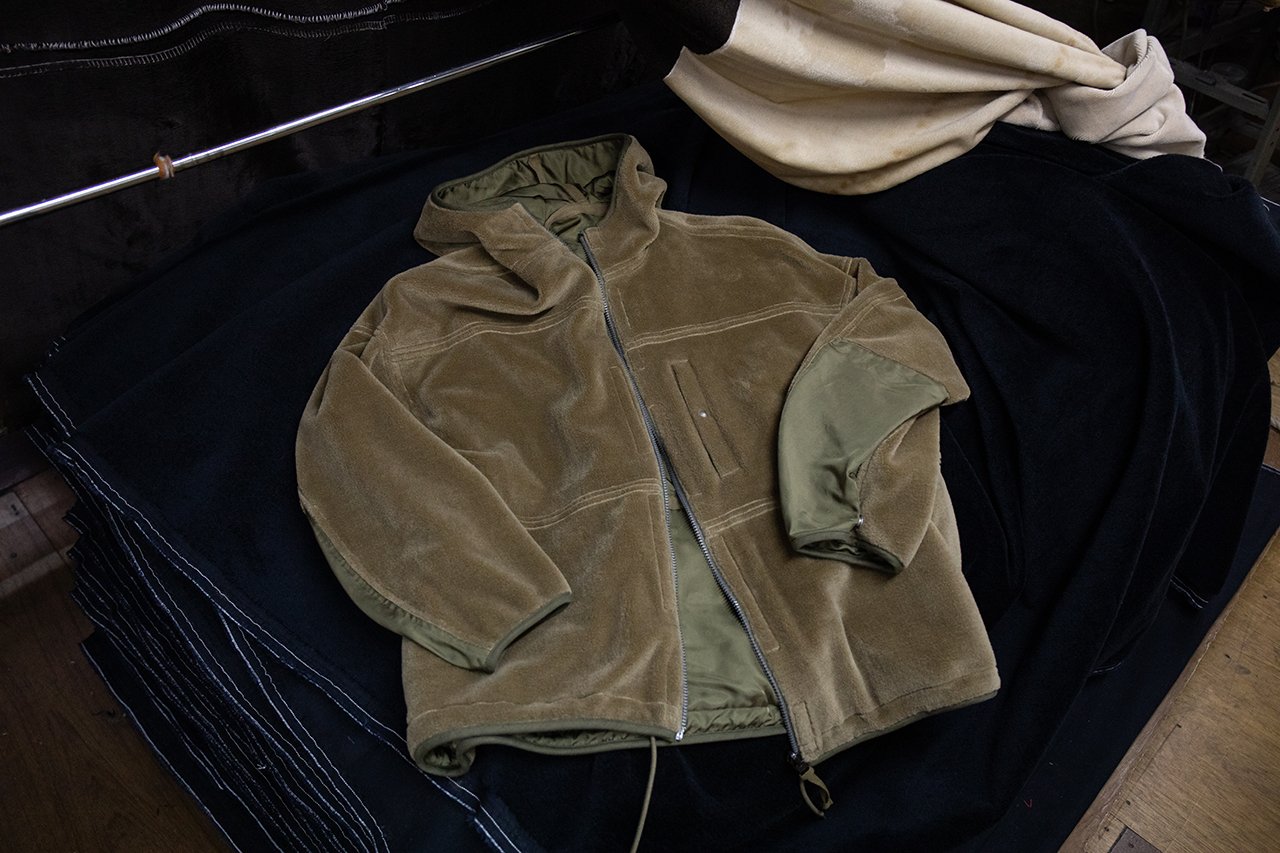

However, pile-woven apparel that uses wool or cotton has existed since before Chouinard's fleece and even the polyester pile sweaters of the fisherman. Some well-known examples are pile-woven military liner jackets, and faux fur hoodie jackets. What made Chouinard's fleece innovative compared to these items was the priority of its waterproofing and the use of synthetic fibers to achieve this.

Carrying the same characteristic insulation and durability of wool but with a lighter weight and quick drying properties, fleece became known as a miracle synthetic fiber. However, how does it compare to wool in terms of texture and comfort? If we rethink the necessary functionality and consider those situations where you don't need to worry about working up a sweat or getting wet from the rain, is there a possibility for a better material that utilizes and retains the texture of natural fibers?

Originally, the word fleece referred to the amount of wool sheared from a single sheep. The word has the connotations of an expressive piece of material that is light, warm, and strong. Returning to this original meaning of the word, high-quality wool is the material of choice for the pile yarn, but what about the foundational fabric--what would happen if you used other materials, such as a densely packed and woven cotton, or a linen that breaks in with more wear and changes beautifully over the years? The durability will be ensured by choosing to weave them instead of knitting them. The development of this new pile fabric started with such thoughts; something unlike the fleece in circulation today that incorporates the advantages of wool and also the unique qualities of natural fibers like cotton and linen.

Pile Fabrics from Koyaguchi

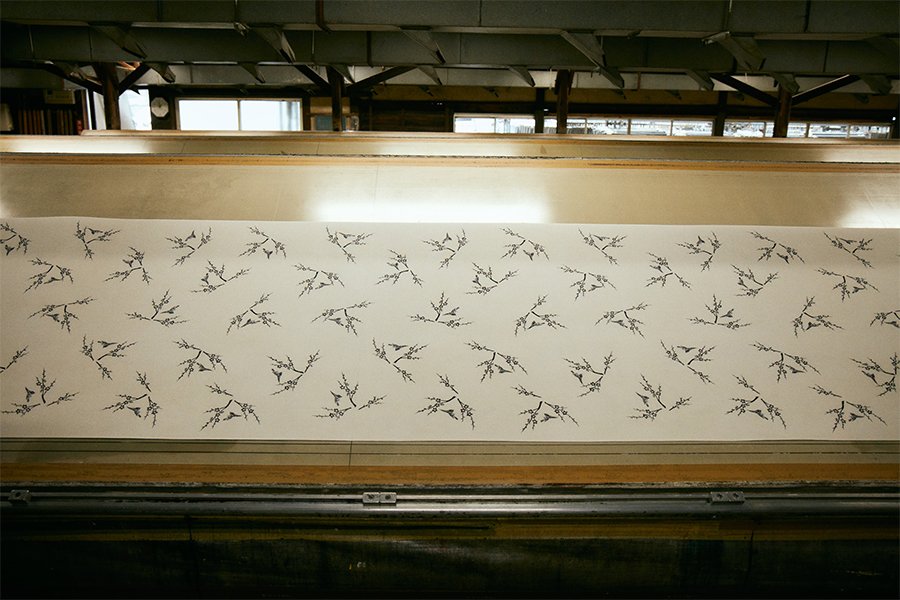

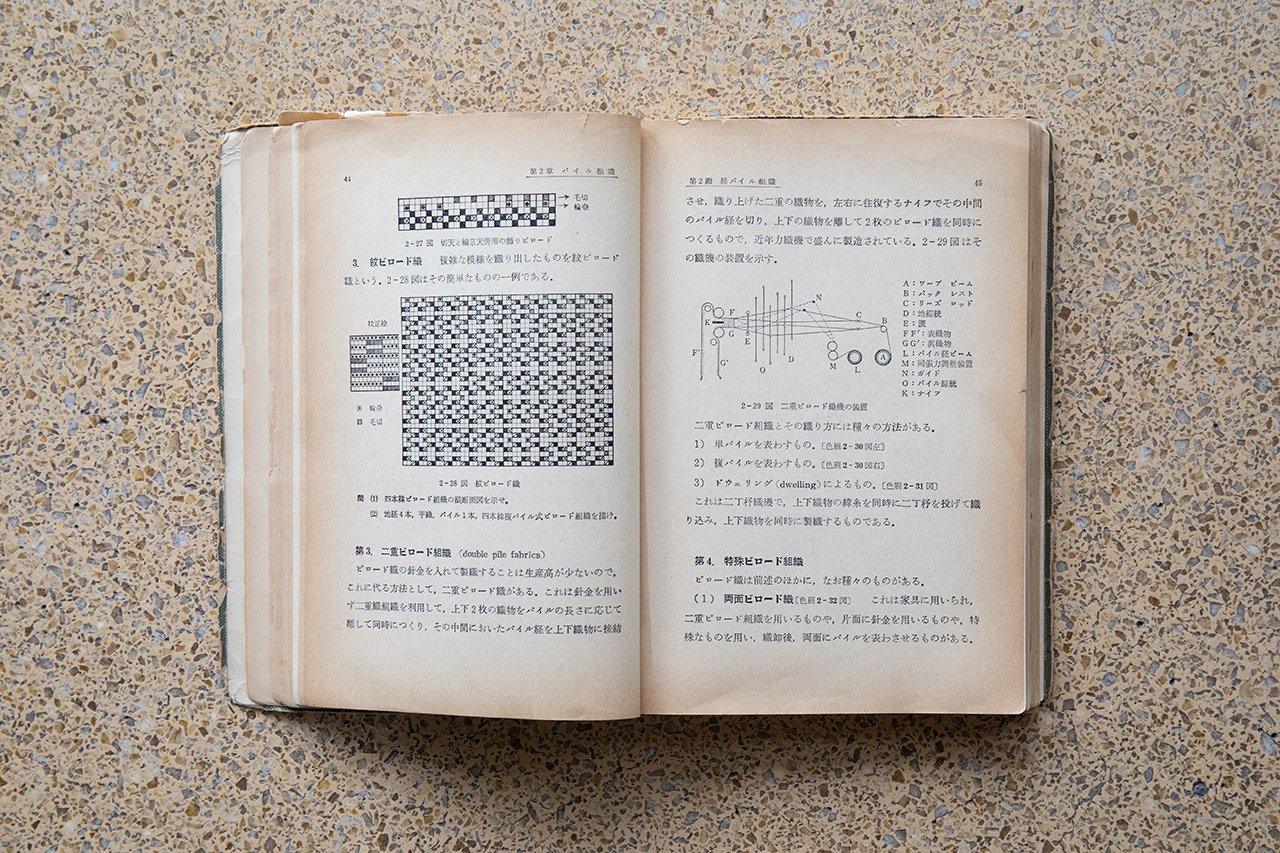

"Pile fabrics" refers to fabric where the surface of a base material contains raised yarn known as "pile". The pile is made from loops of yarn or strands left from trimming the top portion of these loops. You may find pile fabrics being used for seats on trains in Japan or for the upholstery found on sofas.

Koyaguchi is in Northeastern Wakayama Prefecture. This area has long been famous as the gateway for pilgrimages to Mount Koya (Koyasan), however it is also well-known as an area that produces pile fabrics. During the Edo period, the abundant water of the Kinokawa River that flows through the center of the town contributed to increased activity of silkworm raising and weaving (hataori). In the Meiji era, Yasuke Maeda, who was from Koyaguchi, crafted a new process known as "saiori"--literally "repeat weaving." Influenced by chenille fabric from Scotland, Maeda developed a technique where he would cut woven fabric into braid-like threads then would take these threads and weave them again to create a "double-weave" fabric. In the early Taisho era, further research and developments were made to this original process, which eventually contributed to the creation of pile fabric.

Matsuoka Orimono is a woven and knitted pile fabrics establishment that was created in 1933. Their weaving factory finds itself in a lush and verdant location, with the peaks of Mount Koya (Koyasan) in the background and the Kinokawa River nearby. Entering the factory, seven or eight looms--each two meters long and three meters deep--line both sides of a single passageway, working away with a rhythmical mechanical sound.

The process of creating pile fabrics begins with seikei(a process where the raw threads are collected in one strand and tied around a massive roll known as a beam), followed by the weaving process, steaming, thinning of the pile yarn (where the pile yarns are made thinner and softer), shearing (where the excess pile is trimmed to a uniform length), tumble-drying ,then tentering (starching).

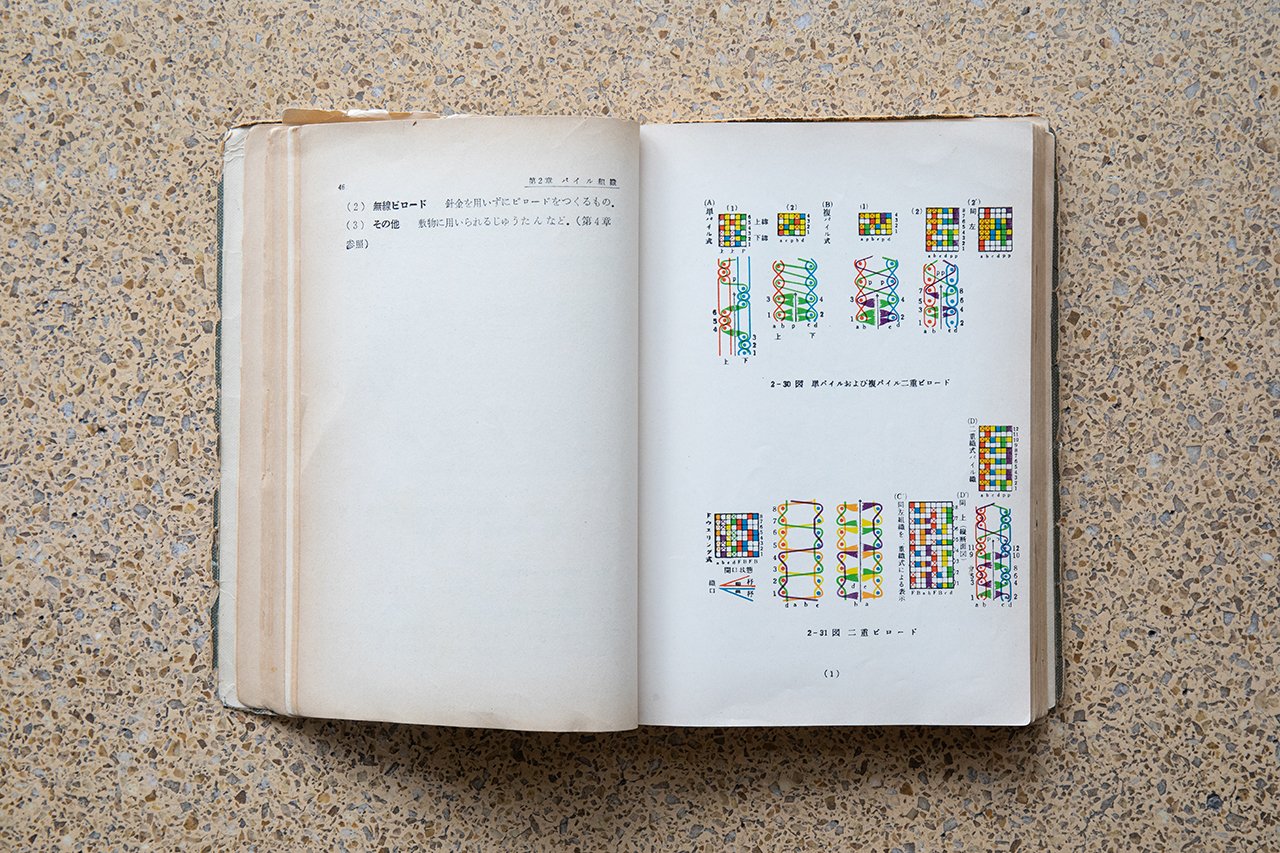

During the weaving process, the loom is set with two layers of fabric--an upper layer and a lower layer, placed face to face--and a long pile warp yarn is woven through the upper and lower fabrics alternately. After the weaving is completed, the pile yarn that connects the upper and lower fabrics are then separated by a knife that slices horizontally through them, resulting in two pieces of pile fabric. The foundational fabric is densely woven so that the pile does not come loose and is also woven in such a way that the fabric covers the back ends of the pile threads. It's a complex process that is difficult to comprehend with just visible diagrams and pictures where even the process of simply setting the pile warp yarn onto one loom can take an entire month.

The completed fabric is then steamed. "The thinning process of the pile yarn is heavily influenced by the application of the steam to the fabric," Mr. Matsuoka of Matsuoka Orimono explains. "If the yarns are too relaxed, the thinning process will be too extreme resulting in the loss of the roughness of the original wool." The temperature as well as the hardness and sharpness of the blades are all adjusted depending on the qualities of the fabric and the desired result of the final product-- these adjustments are all made by hand by skilled craftsman with much experience.

Working with synthetic fibers does not require as much work as this particular fabric. It is rare to use natural fibers such as wool, cotton, or linen to create this type of fabric and as a result it is a tricky process that requires a steady hand from skilled craftsmen to produce this pile fabric that can only be made possible here.

In the decades following the Second World War during Japan's economic boom, 80% of all pile fabrics in Japan were made in Koyaguchi, with all the seats on the bullet trains (shinkansen) proudly being labeled as "MADE IN KOYAGUCHI." However, from the beginning of the bubble period, low-priced goods from abroad started to be imported, causing the production of pile fabrics to dwindle over the years. Not only this, the difficulty in producing woven pile fabrics and the development in knitting techniques meant that woven pile fabrics for clothes began getting replaced by knitted pile fabrics. Against these odds though, in the present, Koyaguchi remains an irreplaceable producer of high quality pile fabrics where they also develop new and exciting techniques alongside products, while still preserving and carrying on the traditions of the past.